- Plant simulation download mod#

- Plant simulation download software#

- Plant simulation download code#

- Plant simulation download trial#

New operators for adding, subtracting, or multiplying a value:Īn improved list and table syntax: You now only enter list ranges using curly brackets. ~= instead of =, compare Tolerance for about equal (~=) comparison. If the iteration was the last iteration, continue exits the loop.Ī changed about equal operator. We added the keyword continue, which skips the rest of the loop iteration and continues with the next iteration. The keyword loop in loops is optionally allowed. The keyword then in if-statements is optionally allowed. Switch-case-end instead of inspect-when-then-end You can now enter control flow statements using the simplified syntax: Simplified control flow statements: The control structures which you can insert with the command Insert Control Structure into your source code, reflect this. &thCall(1:0:0:0.5) - call the method in 1 day and half a secondĭefault arguments: You can define default arguments for formal parameters by entering an assignment operator and the default value after the parameter declaration, for example: param x := 0. A time literal can contain a decimal point and decimal places. A time literal starts with a digit and must contain one or more colons. You can enter time literals into your source code. The backslash will not protect another backslash any longer as in SimTalk 1.0. Improved string literals: In SimTalk 2.0 a backslash ( \) inside of a string literal will only protect double quotes and line breaks.

Plant simulation download mod#

In SimTalk 2.0 the keyword div represents an integer division and the keyword mod represents an integer modulo operation. New div/mod operator: In SimTalk 1.0 the // operator represents an integer division and the \\ operator represents an integer modulo operation.

In SimTalk 2.0 you reference Methods and Variables with a leading & operator, for example var o:object := &Method. Improved referencing of methods and global variables: In SimTalk 1.0 Methods and Variables are referenced with the reference operator. In SimTalk 2.0 you will declare parameters using the keyword param, local variables using the keyword var, and the return value using the keyword -> (hyphen plus right angle bracket). SimTalk 2.0 does not need these keywords.

Plant simulation download code#

In addition, you can enter a semicolon after a statement to add another statement to the same line.Ī simplified body syntax: In SimTalk 1.0 the source code requires the keywords is do end. As you still might want to be able to split a statement and distribute it over several lines, the interpreter automatically determines if the statement is still incomplete and, if this is the case, continues it in the next line. Instead, you can simply enter a single statement into a line. Please visitand to submit a request for the free trials.To convert the source code of all existing Methods in a simulation model to the new syntax, hold down the Shift key, click on the object Basis in the Class Library with the right mouse button and click Convert all Methods to New Syntax.Ī line-controlled syntax: You no longer need to type a semicolon ( ) at the end of each statement.

Plant simulation download trial#

The free 30-day trial licenses for Plant Simulation and RobotExpert are available immediately.

Plant simulation download software#

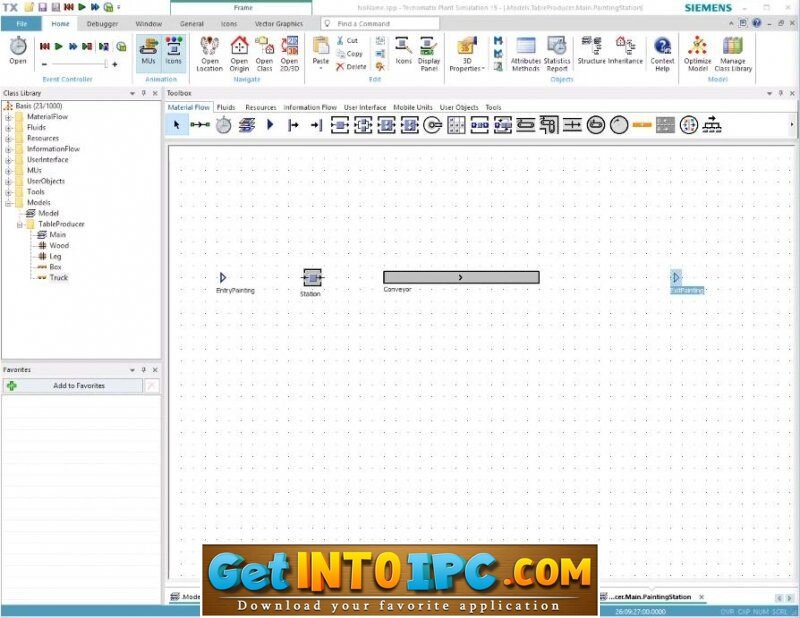

The software can virtually optimize robotic processes thereby reducing system setup time, minimizing downtime and increasing throughput for shop floor robots. RobotExpert is an easy-to-use robotic simulation and offline programming software that helps manufacturers plan and manage their industrial robotic systems efficiently. Plant Simulation is an object oriented and 3D modeling tool used to perform discrete event simulation and value stream mapping.

Plant Simulation is the world’s leading discrete event simulation software used for logistics planning and manufacturing throughput analysis. “By offering a free 30-day trial, we help manufacturers learn and explore how their businesses can benefit from the use of Tecnomatix digital manufacturing applications.” “Industry data shows that manufacturers can increase logistics system productivity by as much as 20 percent through the use of plant simulation software and robotic simulation can increase throughput for shop floor robots,” said Tom Hoffman, director of marketing, Manufacturing Engineering Software, Siemens PLM Software. An offering of Siemens’ product lifecycle management (PLM) software business unit, the software is available at no charge to help manufacturers more easily evaluate how this technology can create value for their business. Siemens announced a free 30-day trial offer for the latest versions of Plant Simulation and RobotExpert software from its industry leading Tecnomatix portfolio for digital manufacturing.

0 kommentar(er)

0 kommentar(er)